Testimonials

Our Testimonials

WHO-GMP CERTIFICATION

World Health Organization (WHO) began when it's constitution came in to force on 7th April 1948. WHO

This date is now celebrated every year as World Health Day. WHO has a staff of 7000 people from 150 countries.

It's headquarter is in Geneva and It is working in 150 countries.

WHO has established detailed guidelines for good manufacturing practice of pharmaceuticals. WHO good manufacturing practices for pharmaceutical products envisages:

1. Quality assurance

2. Sanitation & Hygiene

3. Qualification & Validation

4. Complaints handling system

5. Contract production & analysis

6. Self inspection, quality audits & supplier's audits and approval

7. Training

8. Personal hygiene

9. Premises

10. Equipment

11. Materials

12. Documentation

13. Good practices in production

14. Good practices in quality control

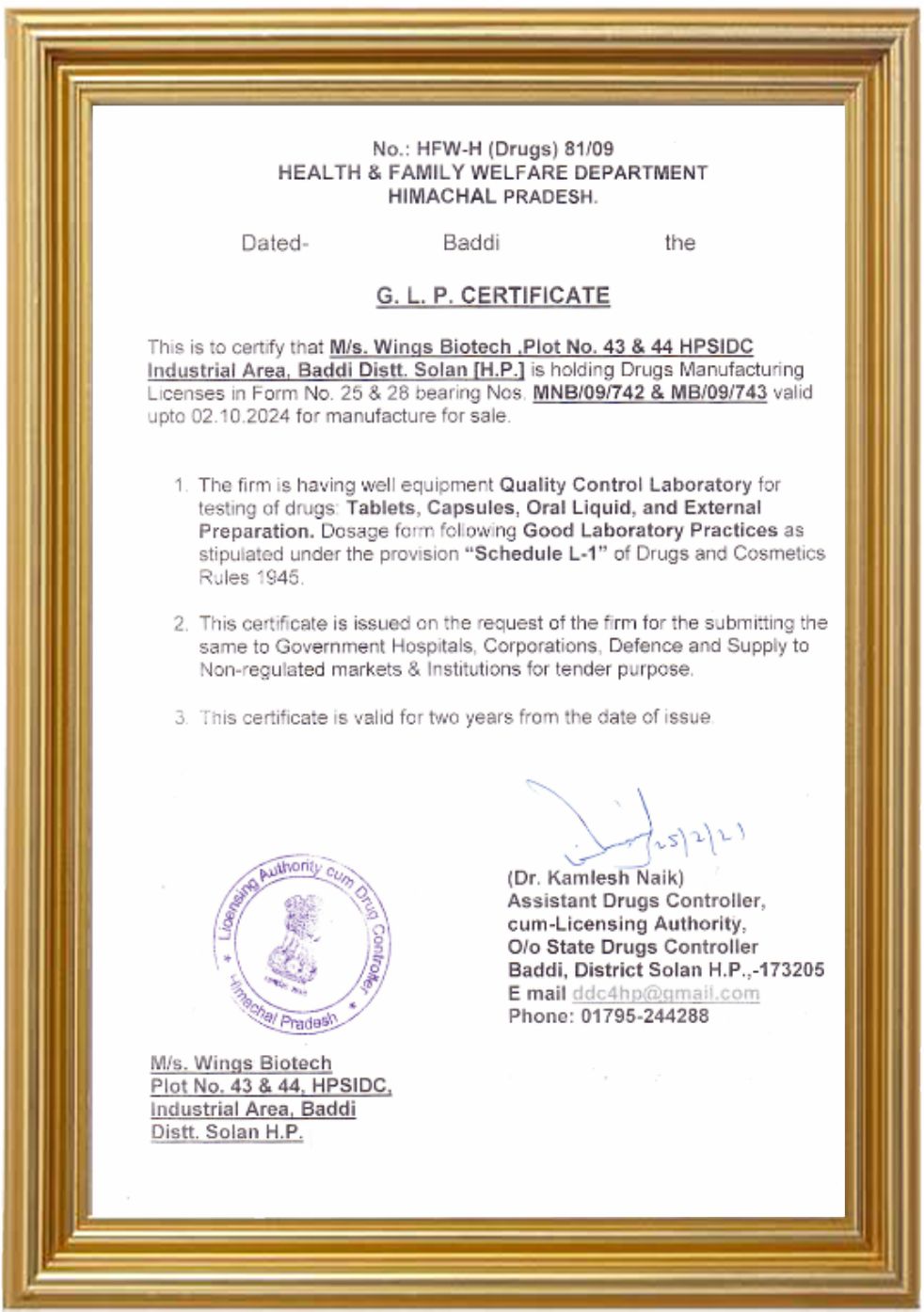

GLP - CERTIFICATION

Good Laboratory Practice (GLP) is a set of principles that guides how laboratory studies are planned, performed, monitored, recorded, reported and archived. GLP helps to ensure the credibility and traceability of data. GLP is intended to minimise adverse drug effects and improve human health and environmental safety profiles. GLP also helps to improve accountability and precision of data through the transparent and detailed documentation of laboratory work while assigning responsibility at various steps in the experiment.

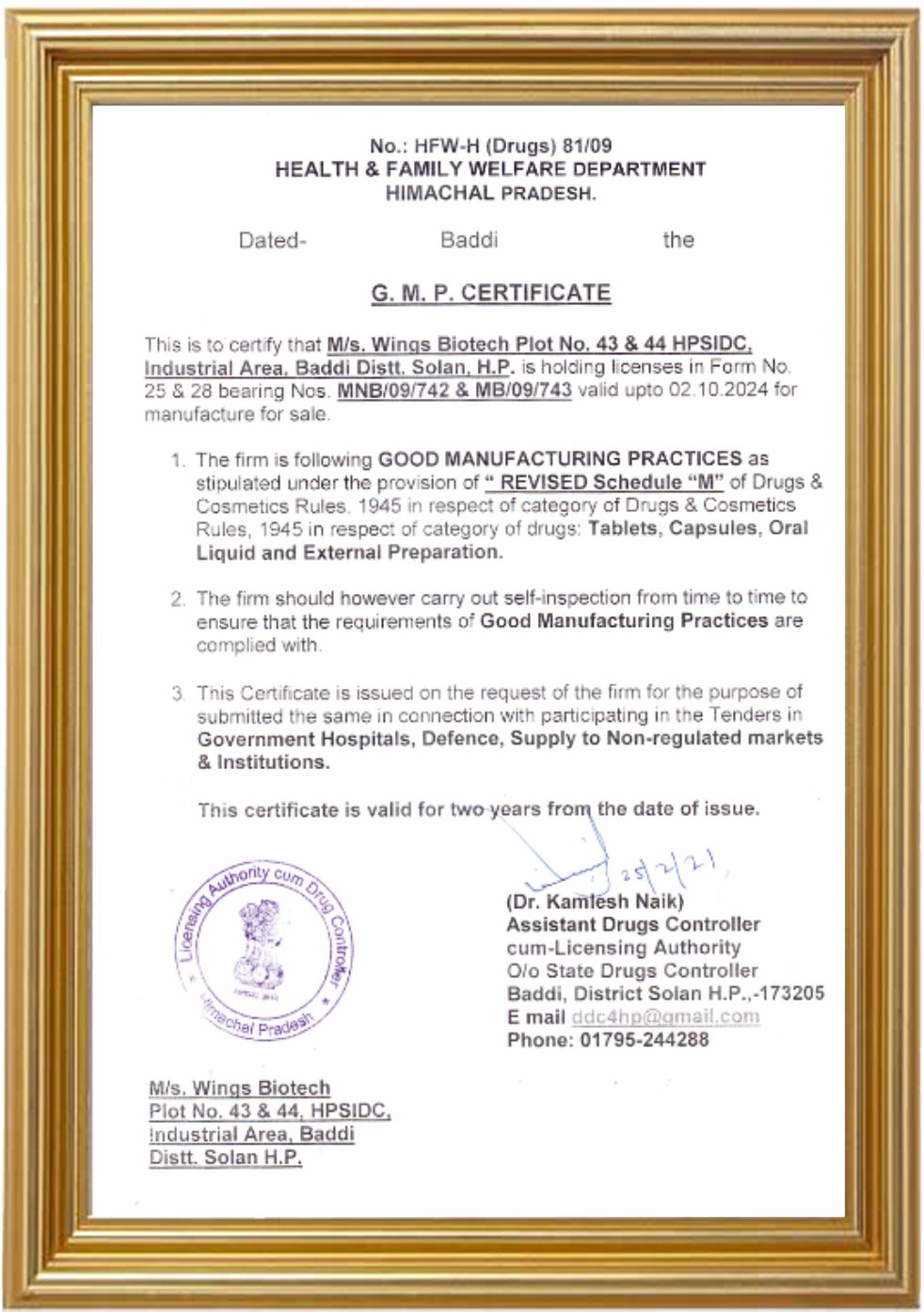

GMP - CERTIFICATION

Good manufacturing practice (GMP) is a system for ensuring that products are consistently produced and controlled according to quality standards. GMP covers all aspects of production; from the starting materials, premises and equipment to the training and personal hygiene of staff. Detailed, written procedures are essential for each process that could affect the quality of the finished product. There must be systems to provide documented proof that correct procedures are consistently followed at each step in the manufacturing process - every time a product is made.